To address the issues of all such recipe/formula-based manufacturers, BatchMaster Manufacturing for Microsoft Dynamics GP has becomes a necessity and not luxury. Dealing with a complex set of challenges, this BatchMaster Mannufacturing built- with Microsoft Great Plains gives businesses the opportunity to:

- Work in a shared environment with a single interface

- Use same credentials for login, and

- Stay connected and informed by sharing a common database

The product safely shares data between the Microsoft Dynamics GP inventory, sales, and purchase modules with the formulation, batch processing, product development, material planning, and other modules.

Right from planning to delivery, BatchMaster Manufacturing for Microsoft Dynamics GP successfully meets the demands of every department—streamlining the production process. This ensures organizations can get consolidated financial accounts, make wiser choices, cut down on waste, improve information analysis of cash flow, and ultimately boost ROI!

Benefits of BatchMaster Manufacturing ERP for Microsoft Dynamics GP

Comprehensive System

A comprehensive system made to handle all aspect of your production schedule, including R&D and formulation, sales and purchases, labour expenses and planning, inventory and batch processing, regulatory compliance, financing, and much more.

Reduced Customization

The Microsoft Dynamics GP-integrated ERP is ideal for industries and sub-industries of Food & Beverages, Pharmaceuticals, Paints & Chemicals, and Cosmetics & Personal Care and is equipped with all solutions for Southeast Asian manufacturers. Thus reducing need of customization.

Control Costs & Losses

Efficiently plann and schedule to guarantee complete process cell utilisation, prompt procurement, no stocking in excess of requirements, and reduce wastage due to expiry & shelf-life.

Increased revenue

Provides precise information ensuring deeperanalysis of consumer trends, encourages businesses to act on it, and equips them with tools like reports, dashboards, charts, and "Smartlists" to deal with the right numbers (like available-to-promise, on hand, sales figures).

Diversified yet Unified

Different modules of the “BatchMaster Manufacturing ERP for Microsoft Dynamics GP” work together to carry out various responsibilities and functions.

Compliance Center

Using this Manufacturing ERP for Microsoft Dynamics GP, manufacturers can easily adhere to all industry standards, best practises, and local requirements, trace & track, print labels & allergens, attach SOPs, handle & dispose of hazardous materials, and manage audits.

Faster ROI: resultant of

BatchMaster ERP integrated with MS Dynamics GP with track record of timely implementation within budgets, regular updates, & upgrades to shifting market trends, new industry compliance, scalability to business growth and less training needs ensures faster ROI.

Enhanced Productivity

Your staff works in a familiar GP environment, utilises Microsoft tools and builds a unique and connected platform using the "Navigation list", allowing grouping individualised tasks under a single working environment, simplifying chores, improving communication, and boosting productivity.

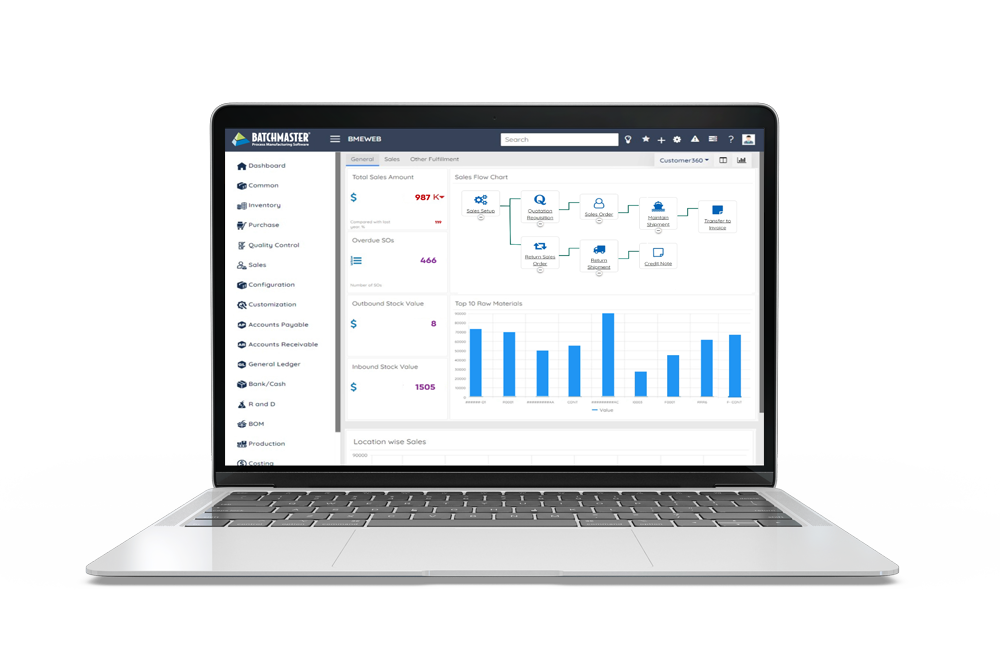

Modules of BatchMaster Manufacturing ERP

Manage Formulas & Recipes

The system creates a simpler and more efficient method for developing and managing complicated formulas and recipes. This Microsoft Dynamics GP for Manufacturing Industries software handles approvals at every level, from research and development to manufacturing, and includes features like version control, material substitution, cost analysis, and formula sizing.

Analyse Costing

Utilize this cutting-edge ERP system to precisely assess the costs involved in the production. Stay relaxed as this effective programme perform a thorough cost analysis of the products both individually and in combination with packaging. With the help of the robust costing module, which is based on Standard, Average, Last Cost, and Base Price, you can perform what-if analysis, achieve target pricing, and compare costs.

Laboratory Module

Intricacies like the physical properties of materials are completely under the control of BatchMaster Manufacturing ERP, giving you access to quick calculations, deeper insights, running numerous equations, analysing physical properties based on target values, and property rollup efficiency. It controls Opportunity and Samples for Manufacturers in addition to tracking and costing items.

Production

Businesses benefit greatly from cutting-edge features like SuperBatch & BatchWithRuns developed by BatchMaster. While BatchWithRuns allows big batches to be divided into smaller units and executable processes, SuperBatch is used to produce intermediate and completed goods in the same batch. The Anytime Batch Sizing, batch substitution, BOM sizing, partial and full close, weight/volume analysis, batch inspection, etc. can be carried out jointly by the production module.

Robust Reporting

With a special tool called "Smart lists," which is intended to manage and trace manufacturing demands, companies can improve compliance & reporting. Numerous analysis tools and dashboards keep you informed of key insights that are applicable to your work or function and provide you the power to make quick decisions.

Quality Analysis

By doing an end-to-end quality analysis on raw materials, during and after production, and lastly on finished goods, you can ensure that the quality of the materials is never compromised. Assign tests and expected results, support pass/fail, numeric, and alphanumeric result types, arrange a retest with a destructive test provision, and avoid using unqualified objects.

MSDS

By adhering to GHS and putting hazard communication protocols into place through SDS, you can experience less complaints and instances of chemical-related occupational diseases & injuries. MSDS automates the creation of Safety Data Sheets, Labels, SARA Reports, Shipping Documents, etc. with a variety of strong features.

MPS/MRP

Depending on expected demand and supply, redesign your manufacturing process and plan purchase with BatchMaster ERP's production modules; MPS/MRP. Moreover, by determining the quantity of raw materials, labour, and equipment needed to manufacture particular items, manufacturers can forecast future production to avoid unfavourable situations.

Integrate. Extend. Excel.

Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

See BatchMaster ERP in Action

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs

BatchMaster Software is one of the market leaders in offering enterprise software solutions for the process manufacturing industries. With an in-depth industry analysis, gained through a vast industry experience with over 2000 implementations worldwide, we clearly understand the unique industry challenges. BatchMaster offers ERP solutions that are apt to support industry specific operations and handles critical processes of the micro-verticals. Process manufacturing companies around the globe have come to rely upon BatchMaster® to manage nearly every aspect of their manufacturing distribution, finance & accounting, Quality Control, Compliance and HR- related operations. With headquarter in Laguna Hills, BatchMaster has its offices in New Jersey, India and New Zealand.